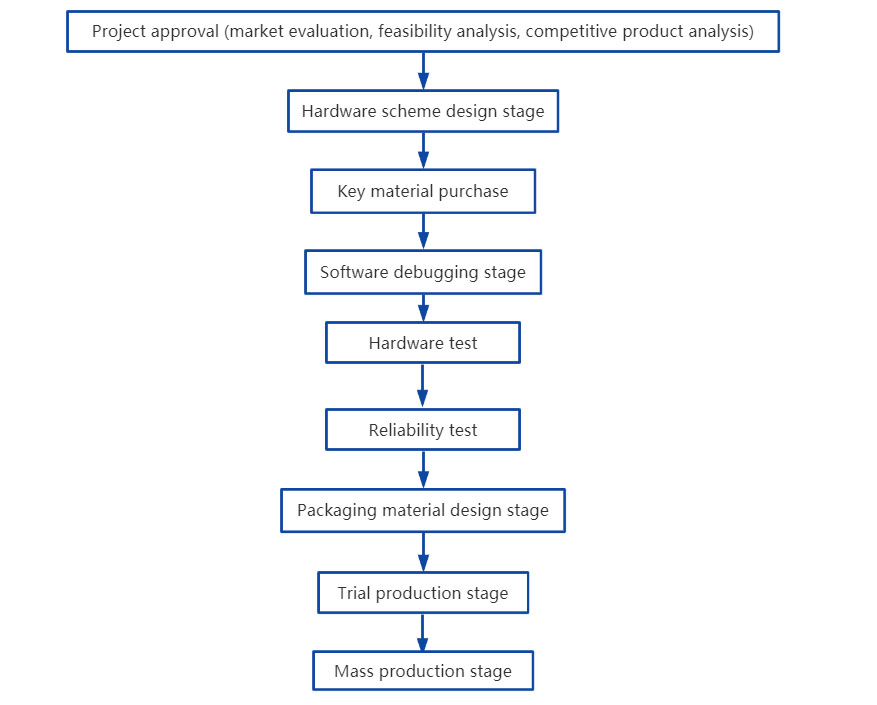

R & D Department

Mr. Chen, the manager of the R&D Department of Hampo Technology, has been deeply involved in the electronic device industry for decades. He is highly professional and has unique insights into this industry. There are three groups under the R&D department, namely R&D group, project group and pilot test group, with more than 15 members, and each member has accumulated several years of experience in this industry.

Quality Department

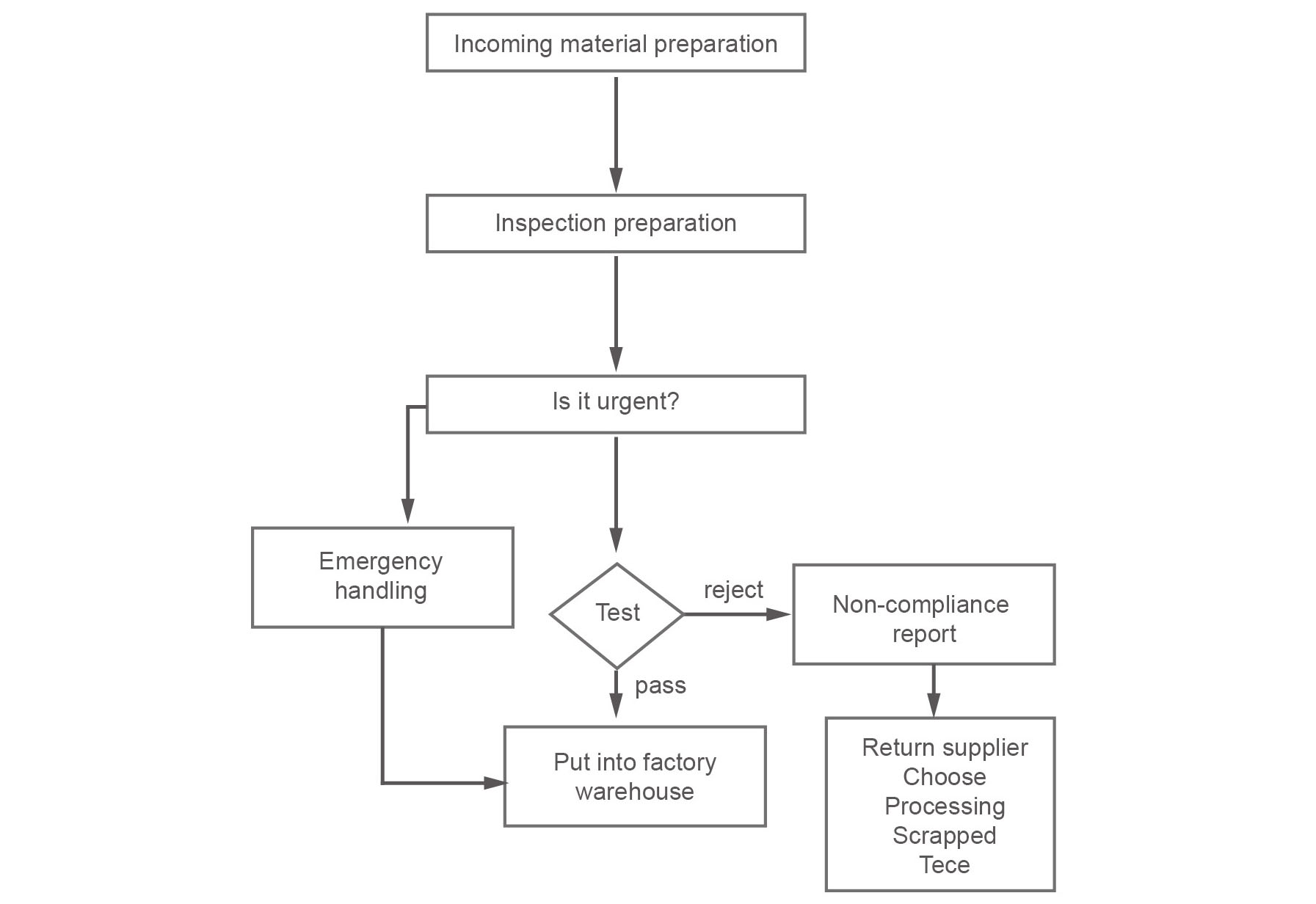

There are more than 50 members of Hampotech Quality Department. The quality requirements of our products have reached the ISO9001 quality management system.

We will inspect incoming materials from suppliers and put them into storage only if they pass the inspection.

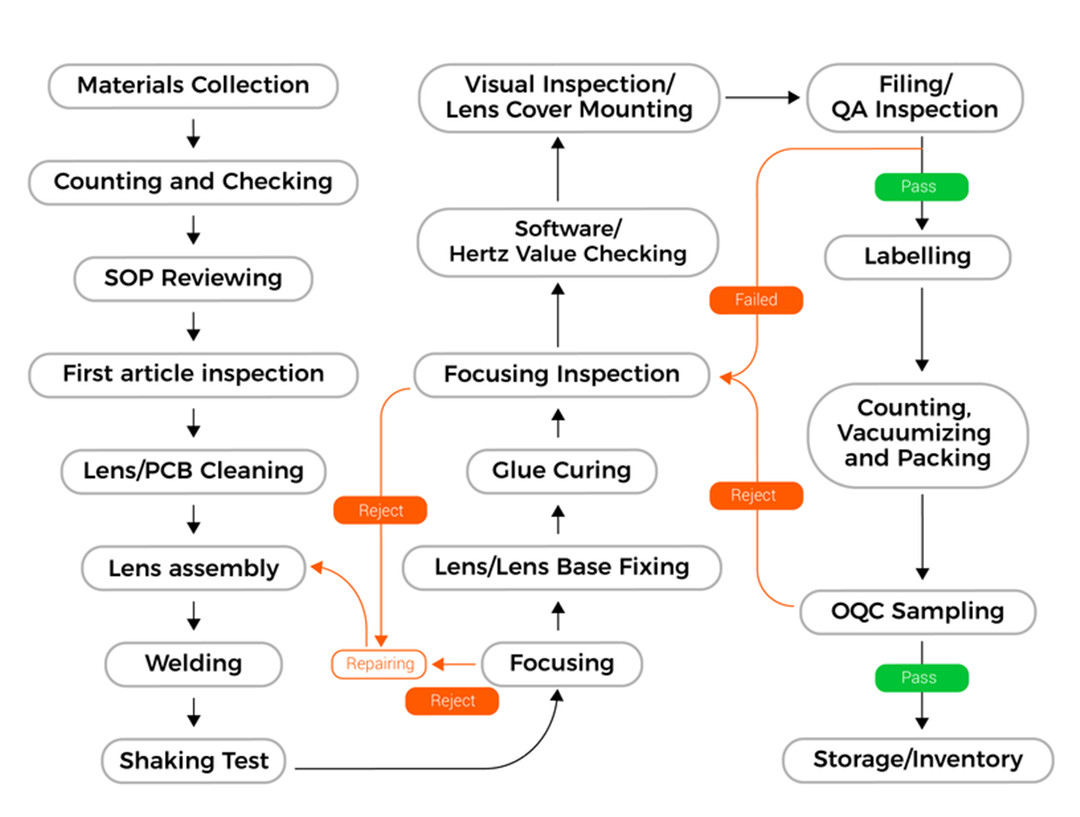

In addition, IPQC will do first article confirmation and process inspection, as well as LQC online full inspection, testing appearance, function, etc. Our products will be randomly inspected according to the standard inspection method before shipment, and will be shipped out only after the pass rate reaches the standard.

Our quality inspection achieves consistent speaking, writing, doing, and memorizing; the inspection equipment and tools will select the most suitable; true record reports.

IPQC

IPQC will test the machine every day when it starts work, and will test whether the materials are correct. IPQC generally adopts random inspection, and the inspection content is generally divided into random inspection of product quality in each process, inspection of operating methods and methods of operators in each process, and point inspection of the content in the control plan.

OQC

OQC inspection process: "sampling→inspection→judgment→shipment", if it is judged as NG, it must be returned to the production line or the responsible department for rework, and then sent for inspection again after rework.

OQC needs to check the appearance of the product, check the size, test the function, and some of them need to do a reliability test to issue a reliability report; the last is to check the product packaging label, issue a qualified shipment report.